QUARTZ RENDER

consumption calculatorDescription

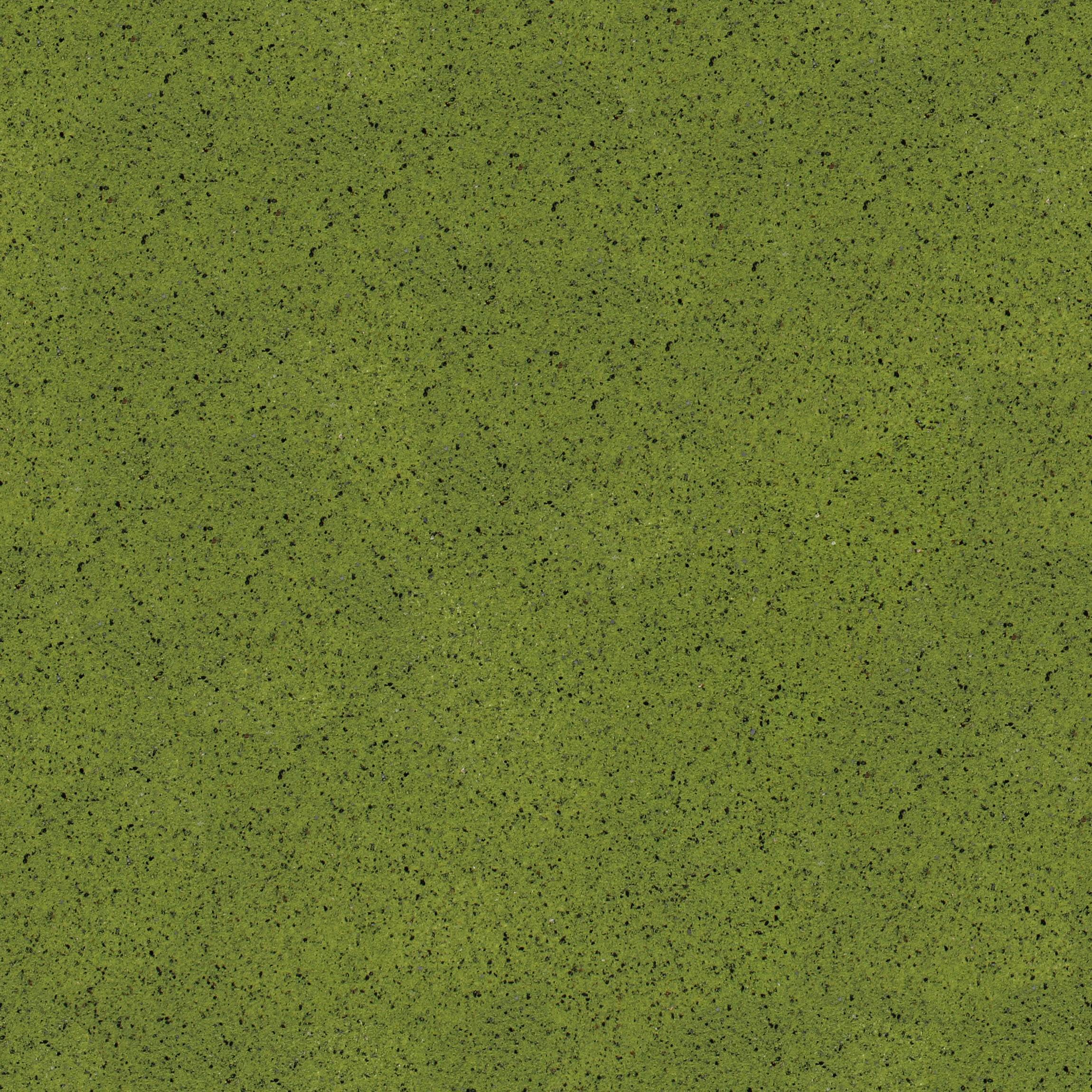

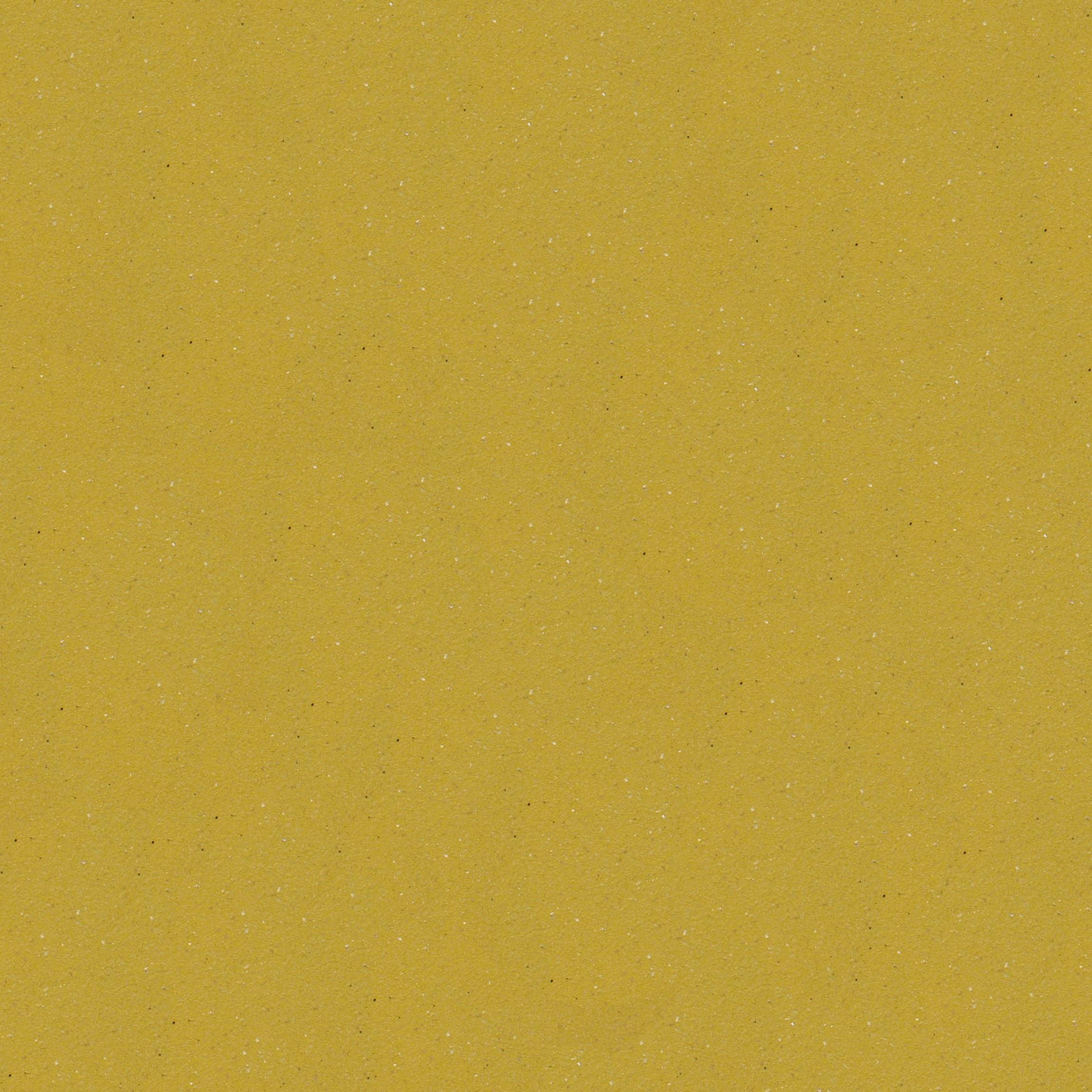

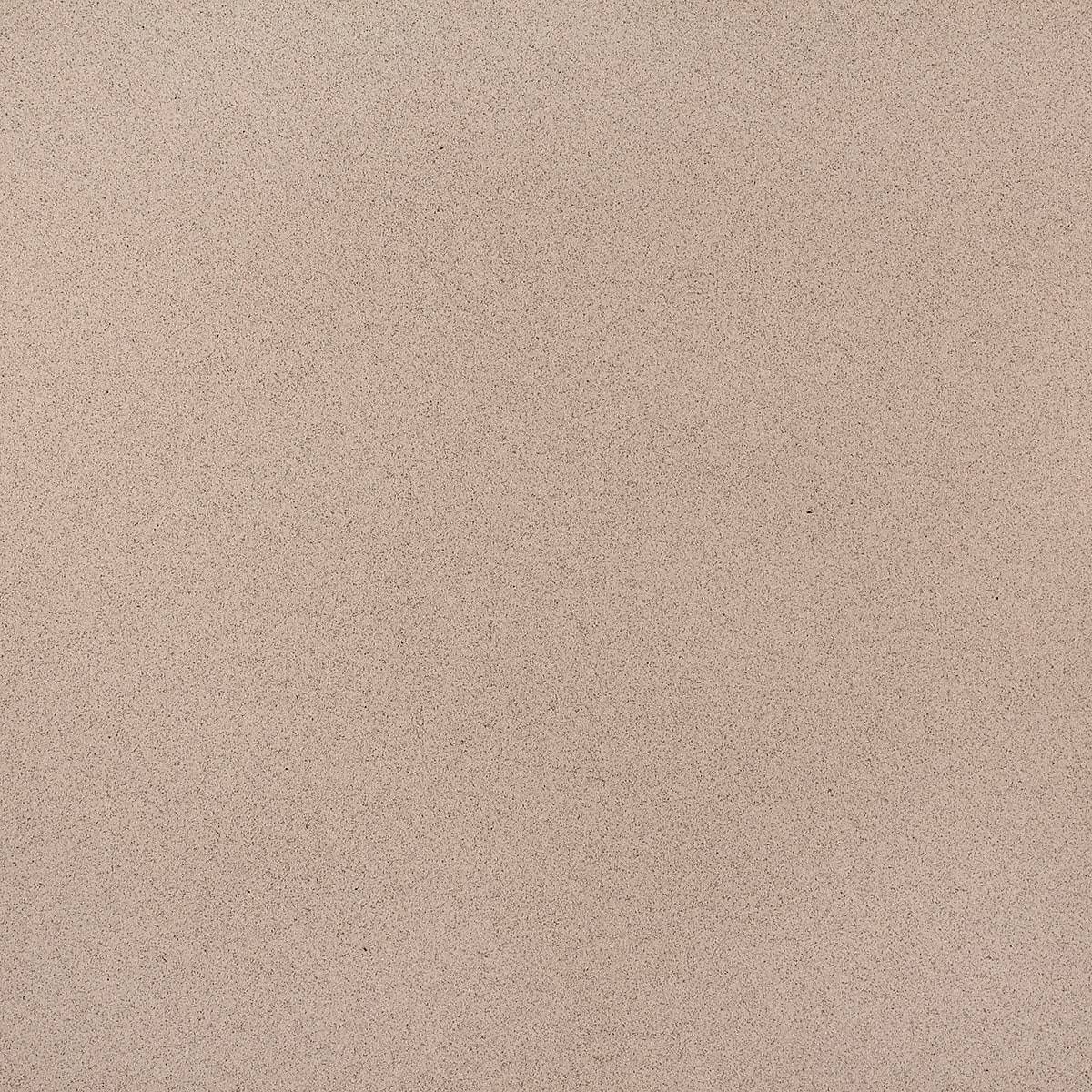

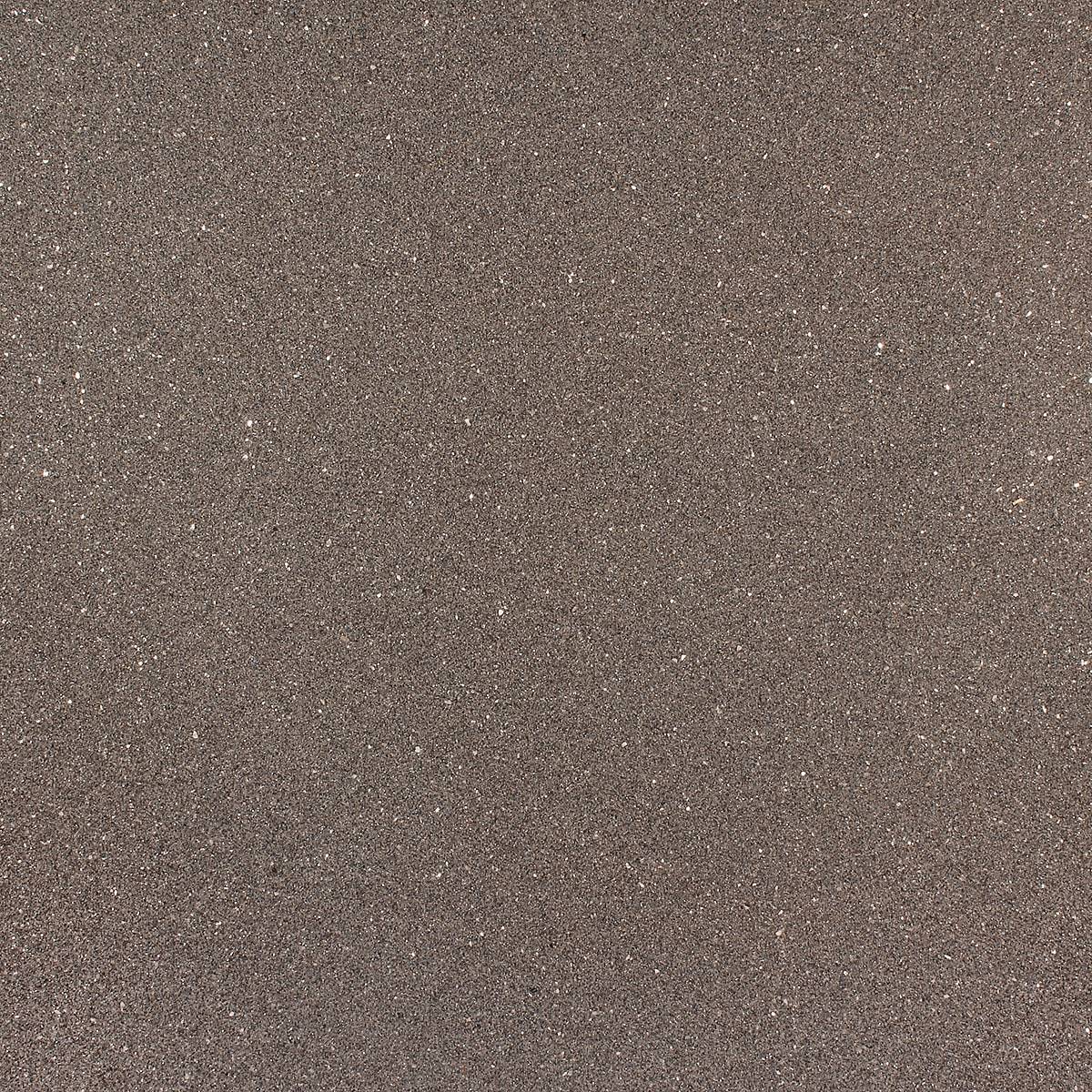

An exclusive decorative render, used to create durable, attractive, thin-layer renderer linings, both indoors and outdoors. Thanks to the high quality resins and carefully selected quartz aggregates, the render provides supreme aesthetics in all three color lines: Natural, Extreme and Colors of the Earth. High resistance parameters and resistance to changing weather conditions ensure that the product is especially recommended as the finishing decorative and protective layer when executing EWI systems based on polystyrene boards and mineral wool.

- - unique alternative to traditional renders

- - perfect for creating a stone or brick effect with decorative templates

- - imitates granite, sandstone and other natural stones

- - exceptional decorative effect

- - for use indoors and outdoors

- - high resistance to mechanical damage and weather conditions

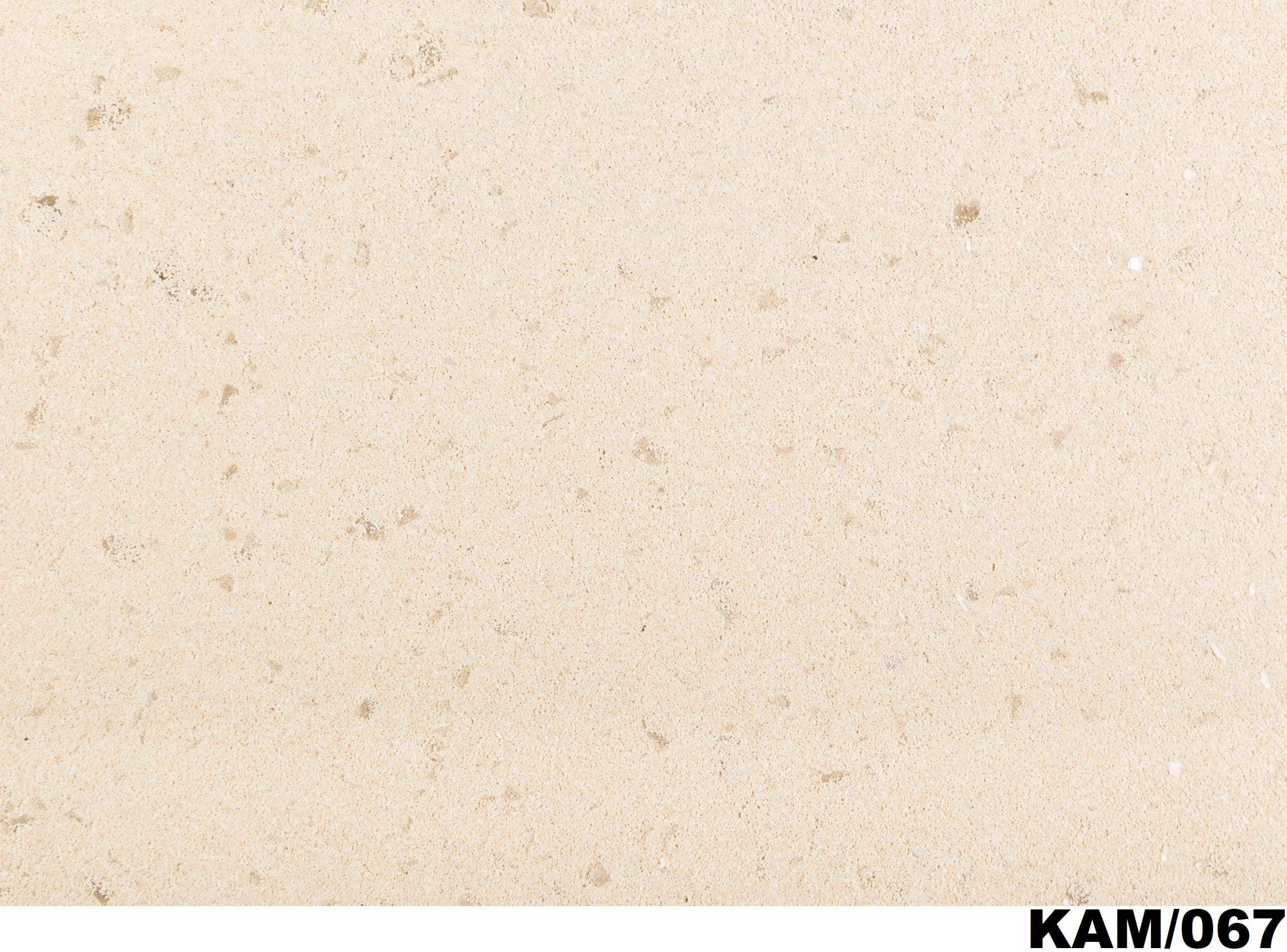

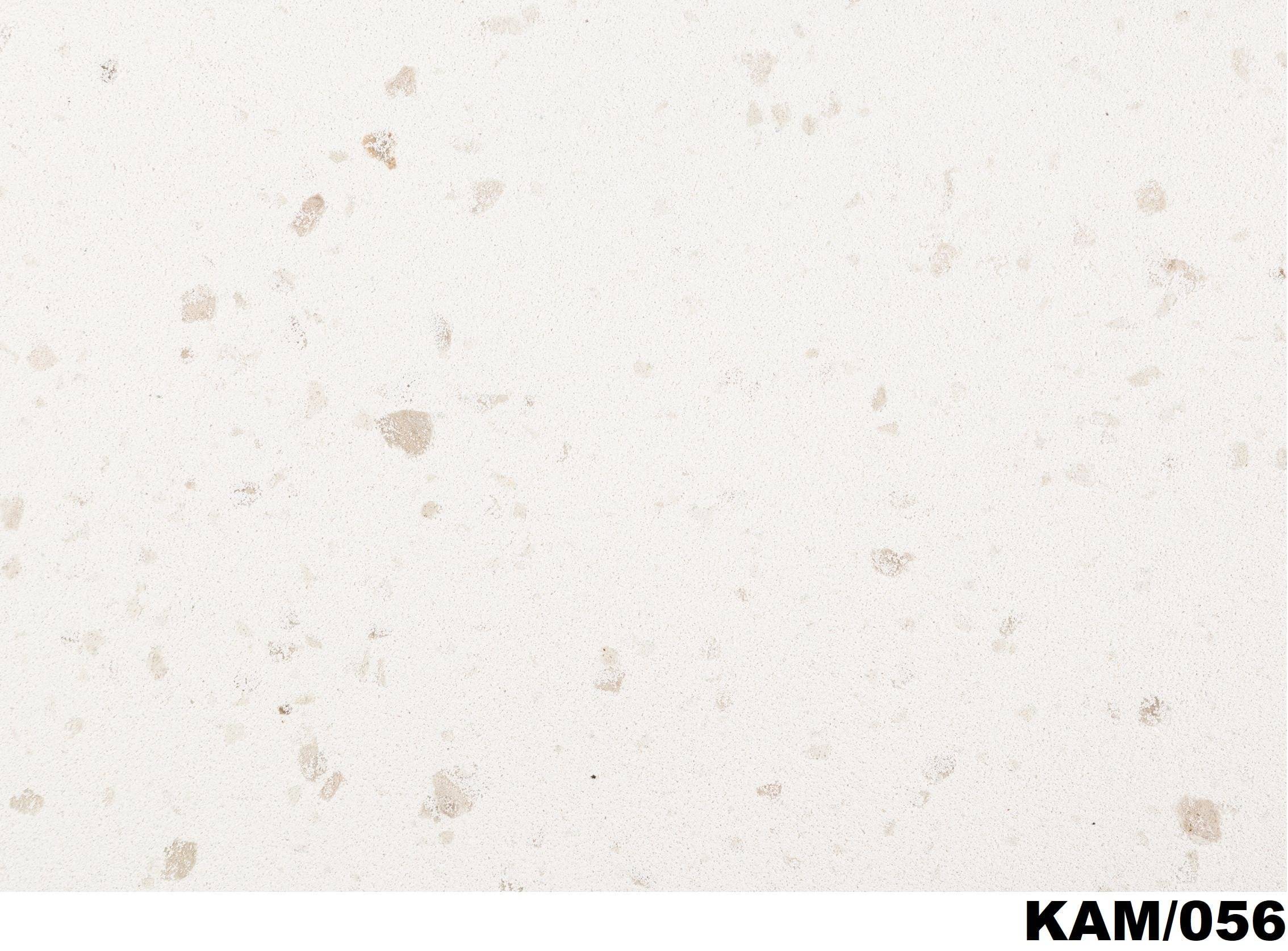

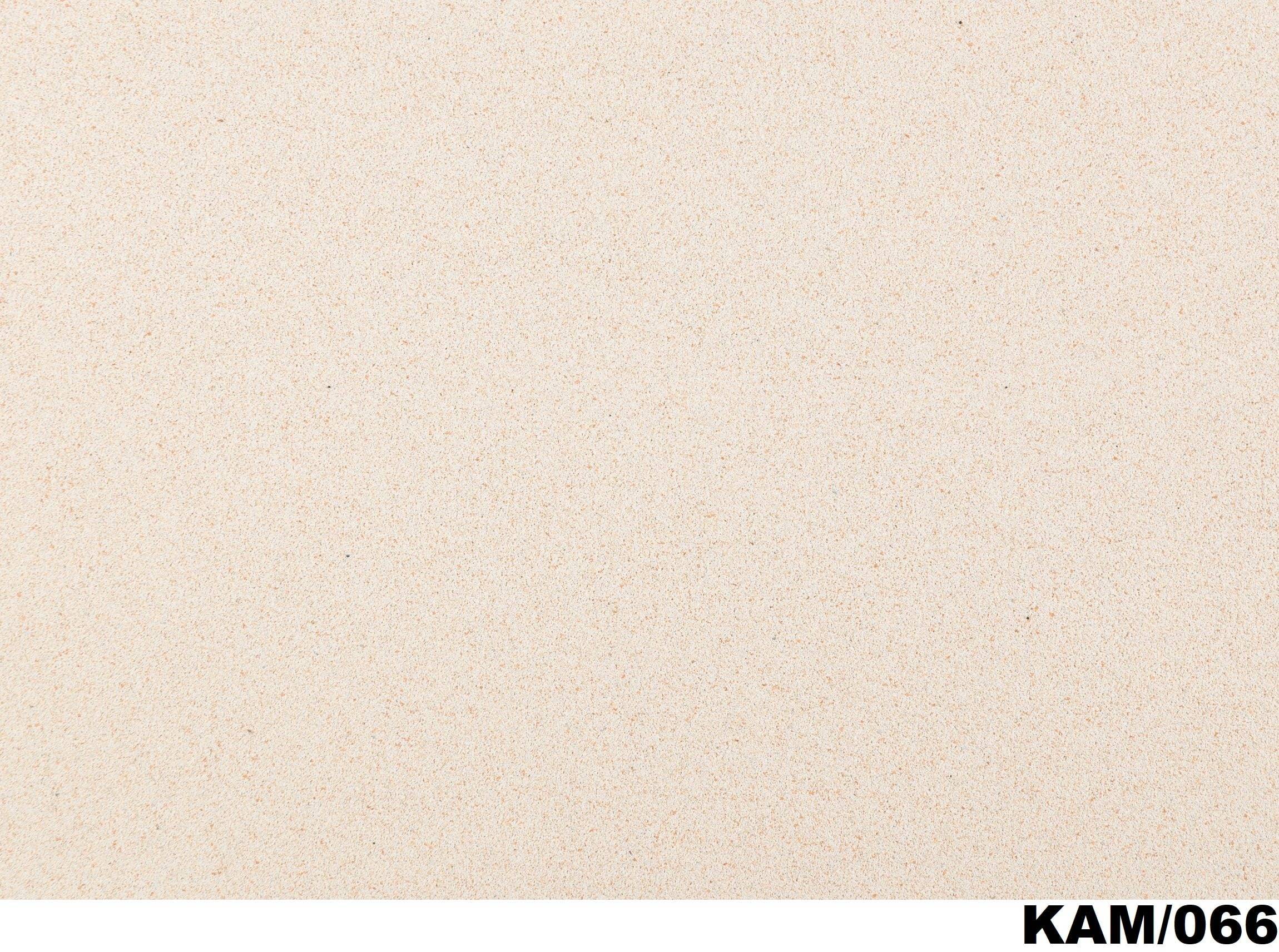

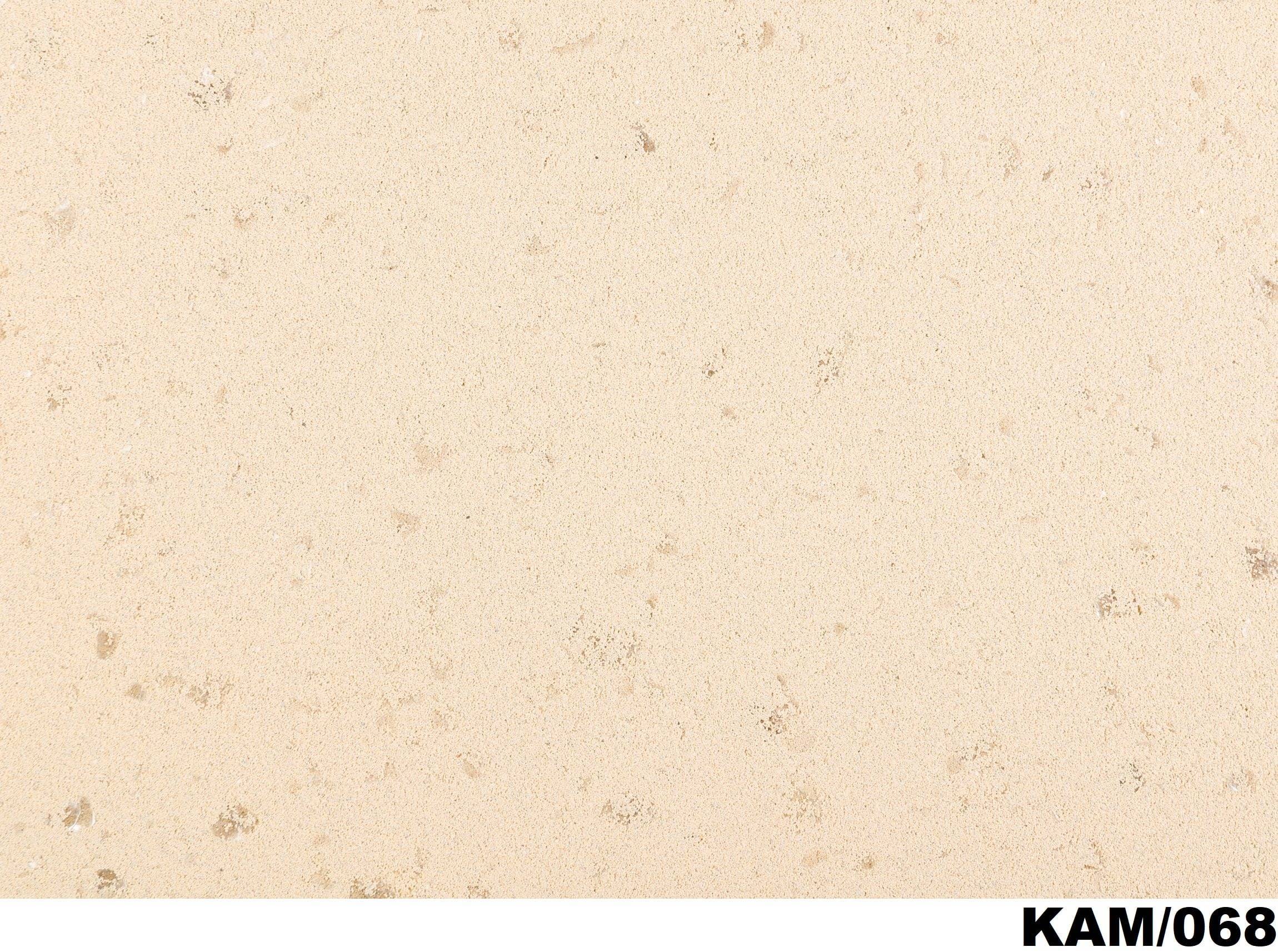

The quartz render by Francesco GUARDI is designed for thin-coat decorative and protective renders both inside and outside of buildings – including entire façades in single and multi-family housing types. It is great for coating heavy-use areas such as plinths, corridors or stairways, as well as ornamental coating of walls indoors. Quartz render is dedicated for spray application (colors from KAM/001 to KAM/055) and for manual application with a steel trowel (colors from KAM/056 to KAM/069 - STONE EDITION collection).

Application

Garage

exterior walls

Hall/vestibule

How to use

SURFACE PREPARATION

Francesco GUARDI Quartz Render needs to be applied on hard, permanent, and perfectly smooth surfaces. The surface needs to be clean, dry, and free of dust, fat, and other substances decreasing adherence. Before applying the render, make sure to prime the well-dried and well-cured surface with a Francesco GUARDI priming agent in a colour similar to the colour of the render. New cement and cement-lime surfaces should be primed no sooner than 4 weeks after their completion. You may apply quartz render after the priming agent has dried, i.e. no sooner than 24 hours after priming in optimum drying conditions (temperature at 20+/-2°C, humidity at ca. 60%).

USAGE.

Spray application: Before use, dilute the product with water max. up to 4% (for 20 kg of plaster up to 0.8 litres of water, for 10 kg of render up to 0.4 litres of water) and mix thoroughly with a low-speed mixer. The prepared mass should be applied with a rendering kit recommended by LAKMA. Spray the stream of render perpendicular to the wall surface from a distance of 40-50 cm, preferably in two layers. The spray gun should be guided in a uniform motion on the surface forming a separate whole. Spray in a circular, vertical or horizontal motion, combining the "wet on wet" layers. Apply the second (levelling) layer immediately after the first one or after it is completely dry. Recommended nozzle for gun no. 2 and 3, pressure in the compressor from 4.0 - 5.0 atm.

Manual application with a trowel (only colours from the STONE EDITION collection: KAM/056 - KAM/069): Before use, mix the product thoroughly with a low-speed mixer. Do not dilute. The render should be applied with a stainless steel trowel to a thickness slightly greater than thickness of a grain, and then carefully smoothed so as not to "stretch" the render excessively. If necessary, you may apply a second layer of render, which should then be smoothed with a steel or plastic trowel.

ADDITIONAL INFORMATION.

Due to natural raw materials in the render, in order to achieve the best visual results, we recommend to use render from a single batch for a separate surface in a given stage. Applying Francesco GUARDI Quartz Render should be done in ground and ambient temperatures between +5°C and +25’0, avoiding direct sunlight during application of render, and during the dry-up phase. Do not apply if air humidity exceeds 80%. Mixing render for too long, or mixing it at high speed may discolour the aggregate, and foam the resin. LAKMA® SAT cannot be held responsible for the quality of work in cases of non-compliance to the stated regulations. Exterior surfaces should be sheltered from rain for 24 hours. The more smooth the surface, the easier the application, and the more visually pleasing is the end effect. Quartz render to be used in the whole of a particular investment must be manufactured on the basis of quartz aggregate from one and the same production batch. Otherwise the quartz aggregate or the render ready to be used should be mixed in such proportions as would make it possible to achieves homogenous colour.

Technical specification

Drying time

24 hours

Number of layers

1-2 depending on the desired effect

1-2

Manufacturer colour

KAM/001

KAM/001 - KAM/055 - for spraying

KAM/056 - KAM/069 - for application with a trowel

Application method

rendering spraying unit

trowel

packaging options

10Kg | 20Kg

Coverage

2,1 – 2,5 kg/m²

2,2 - 2,85 kg/m² (one coat)

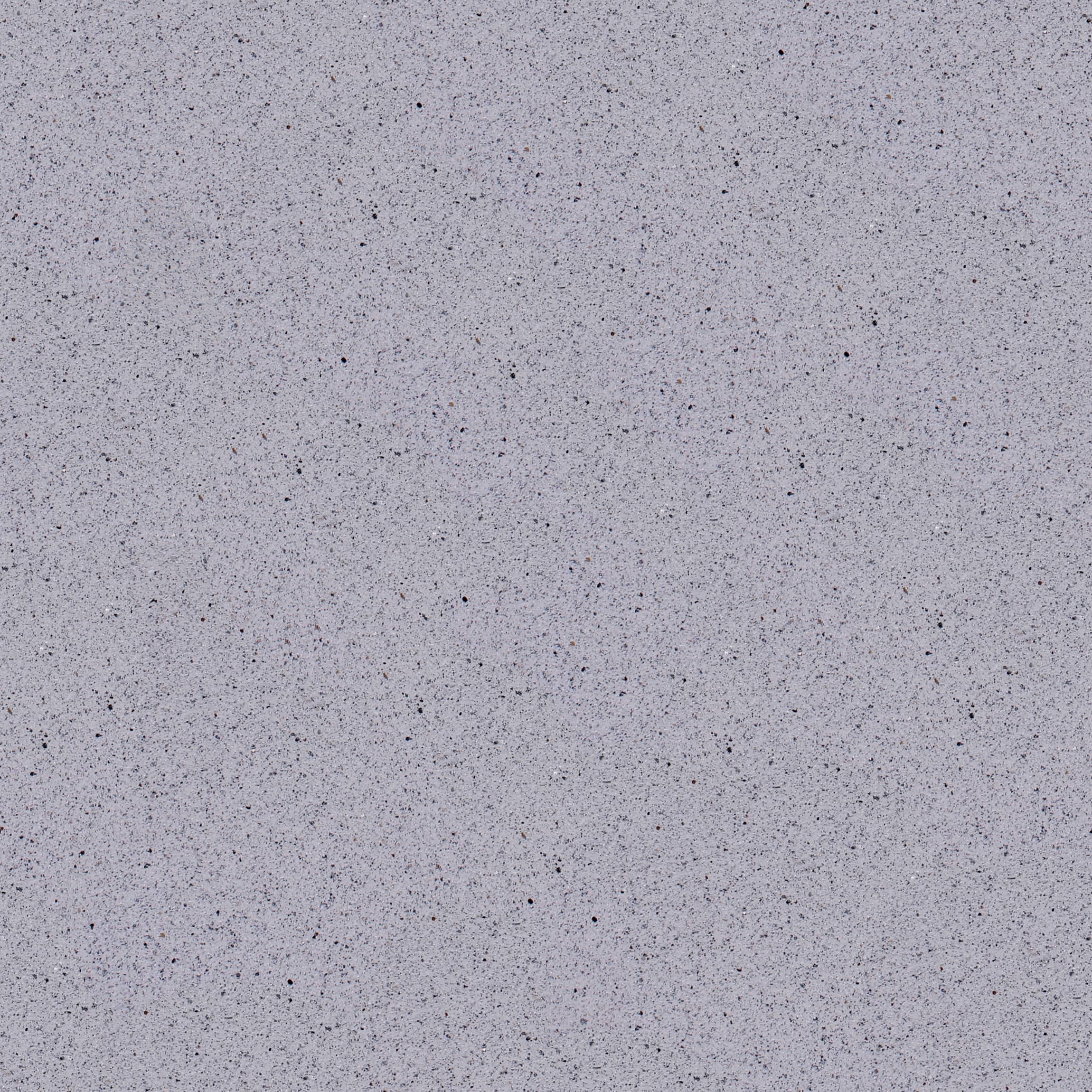

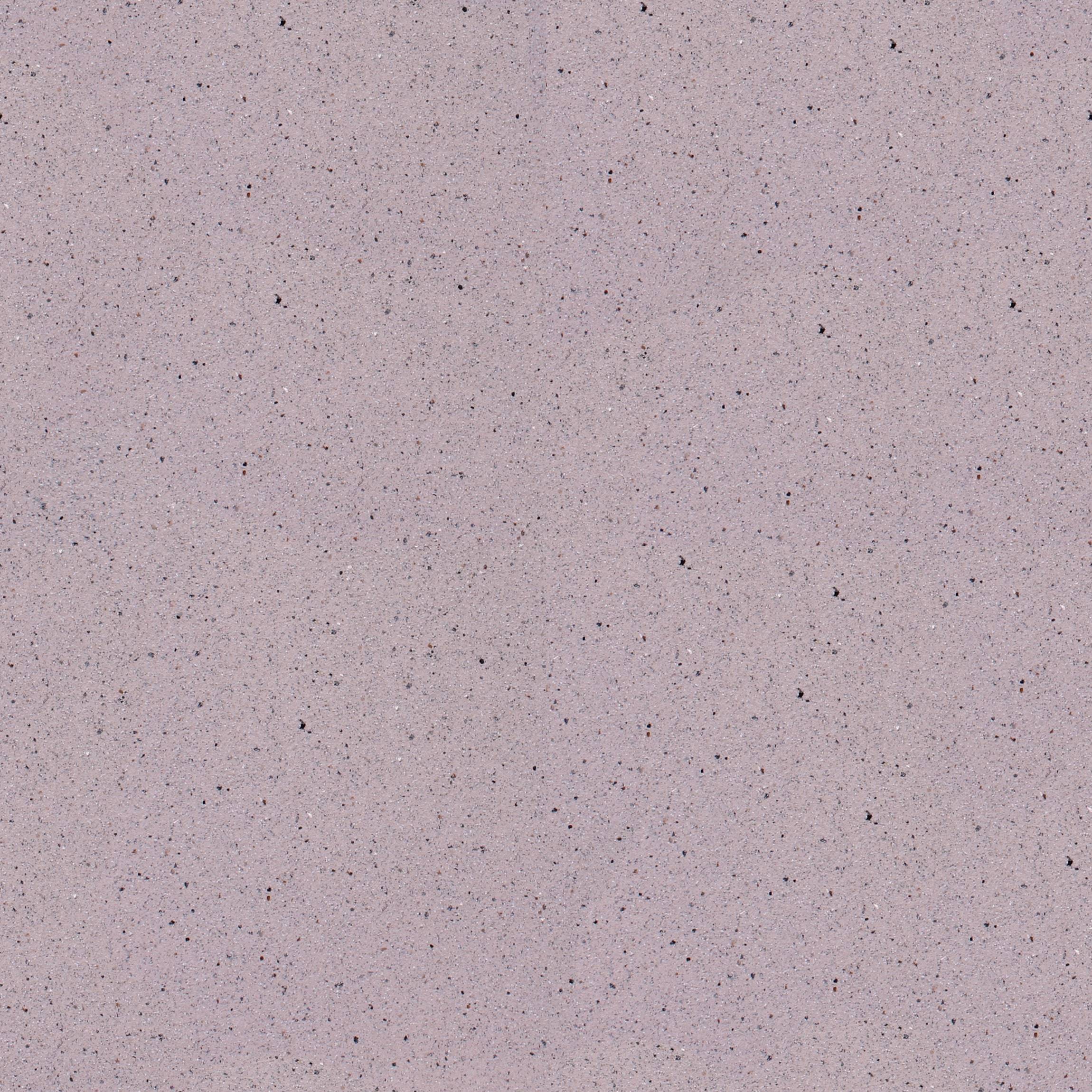

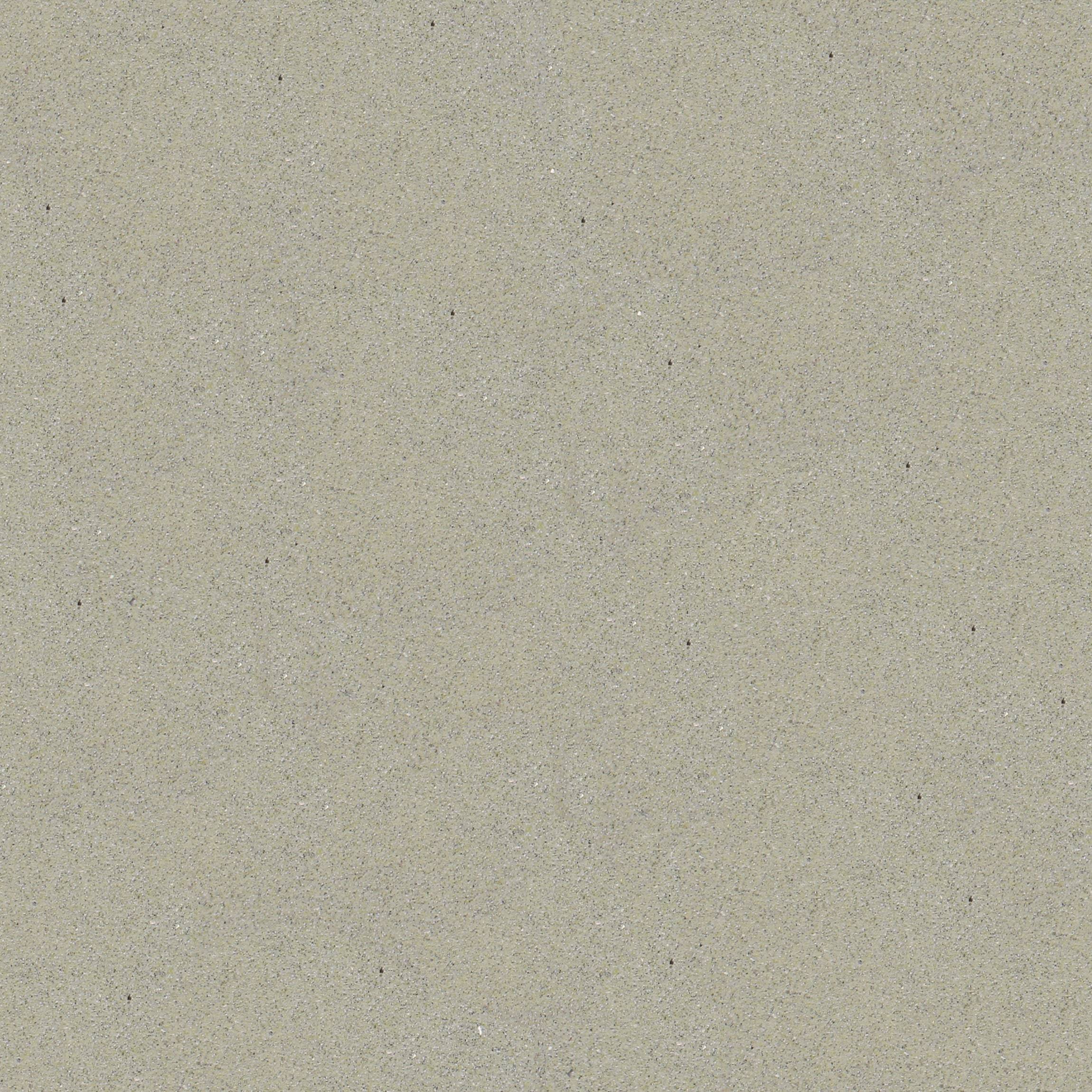

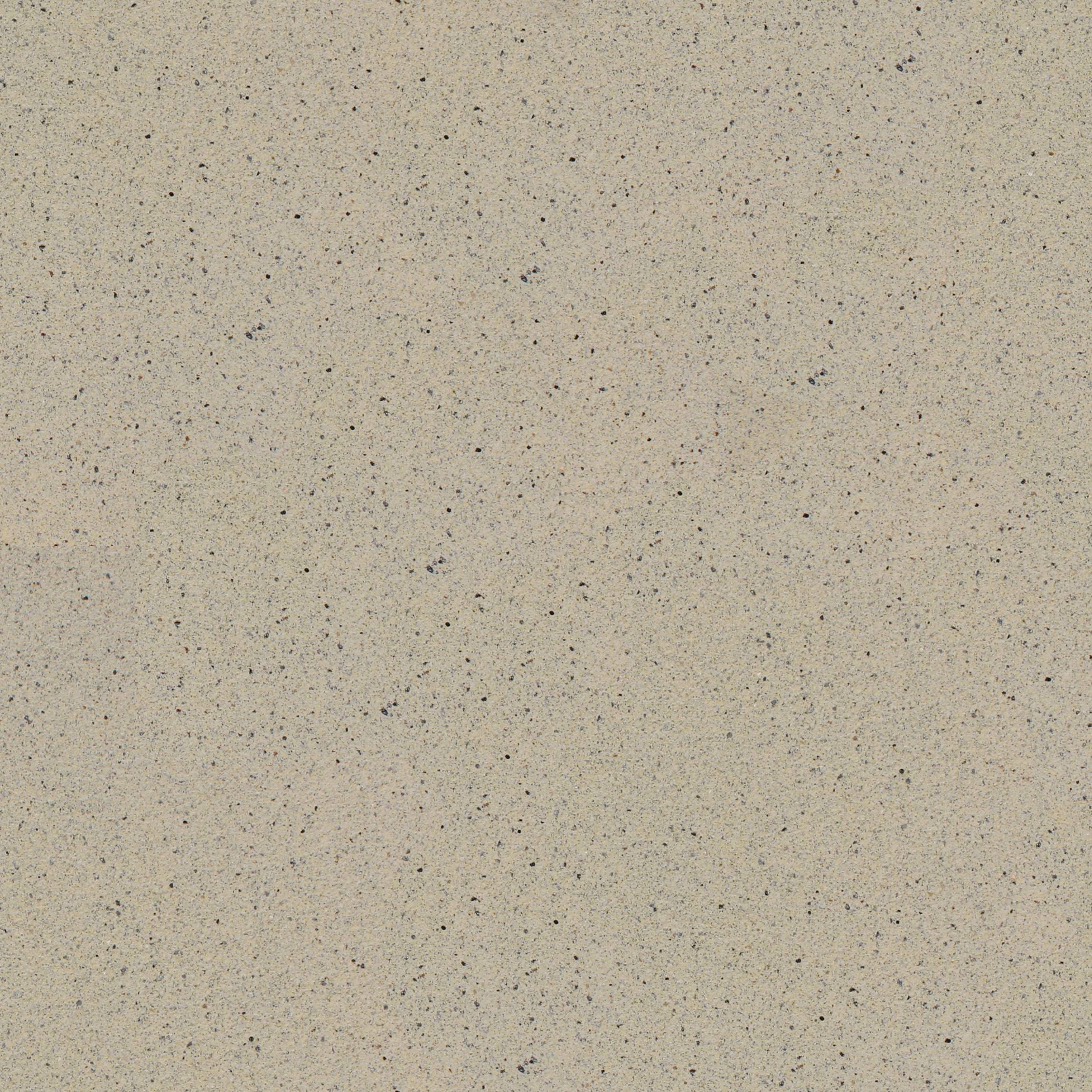

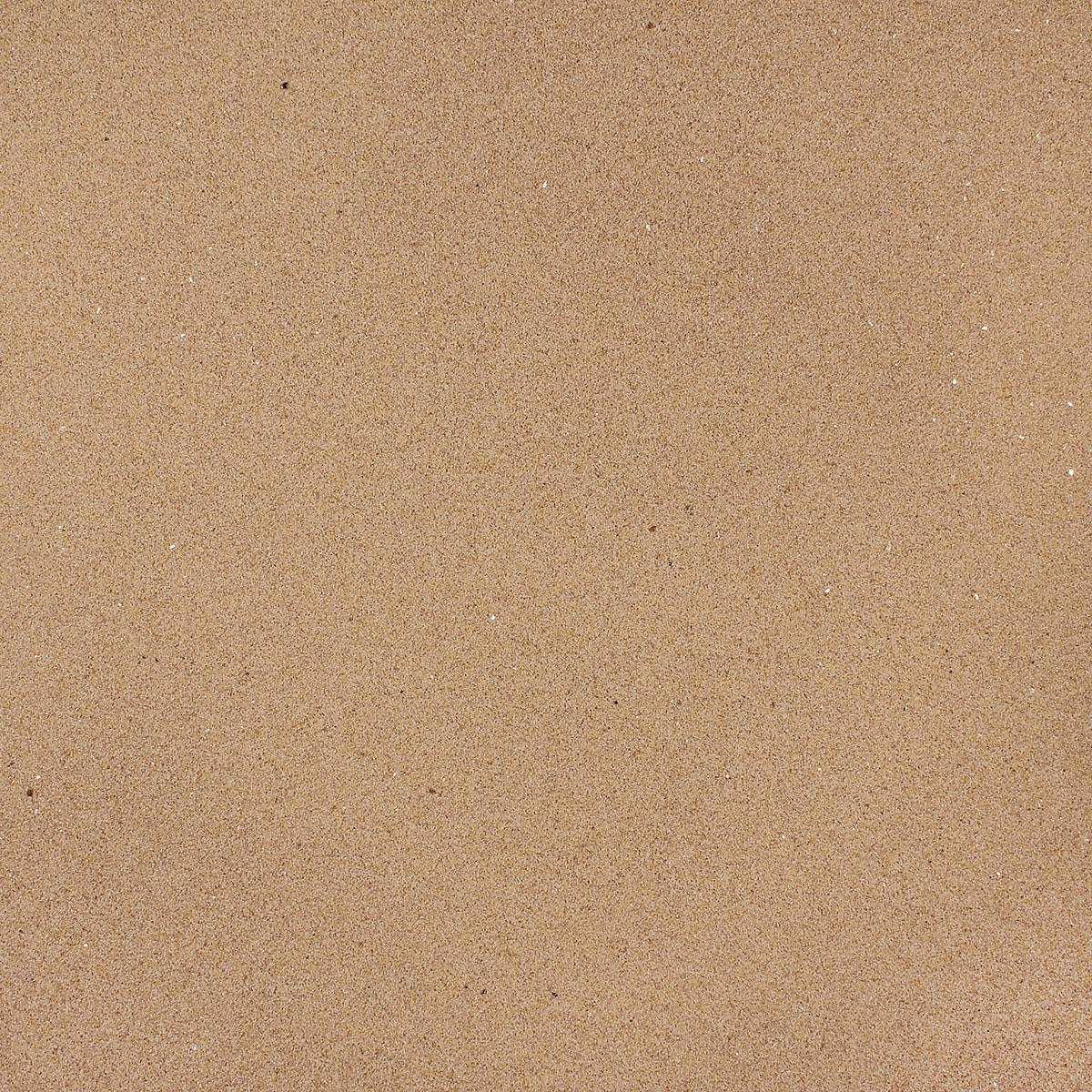

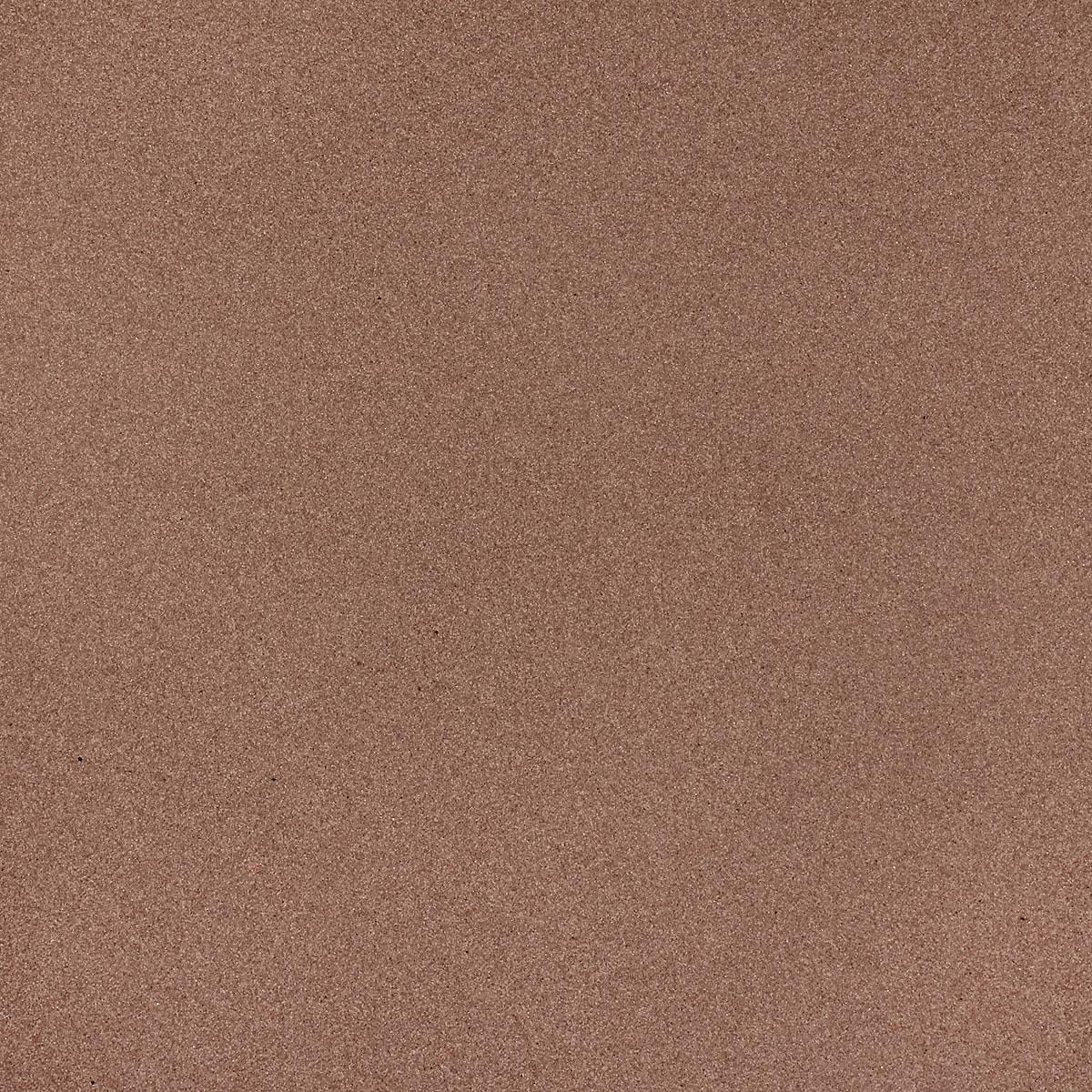

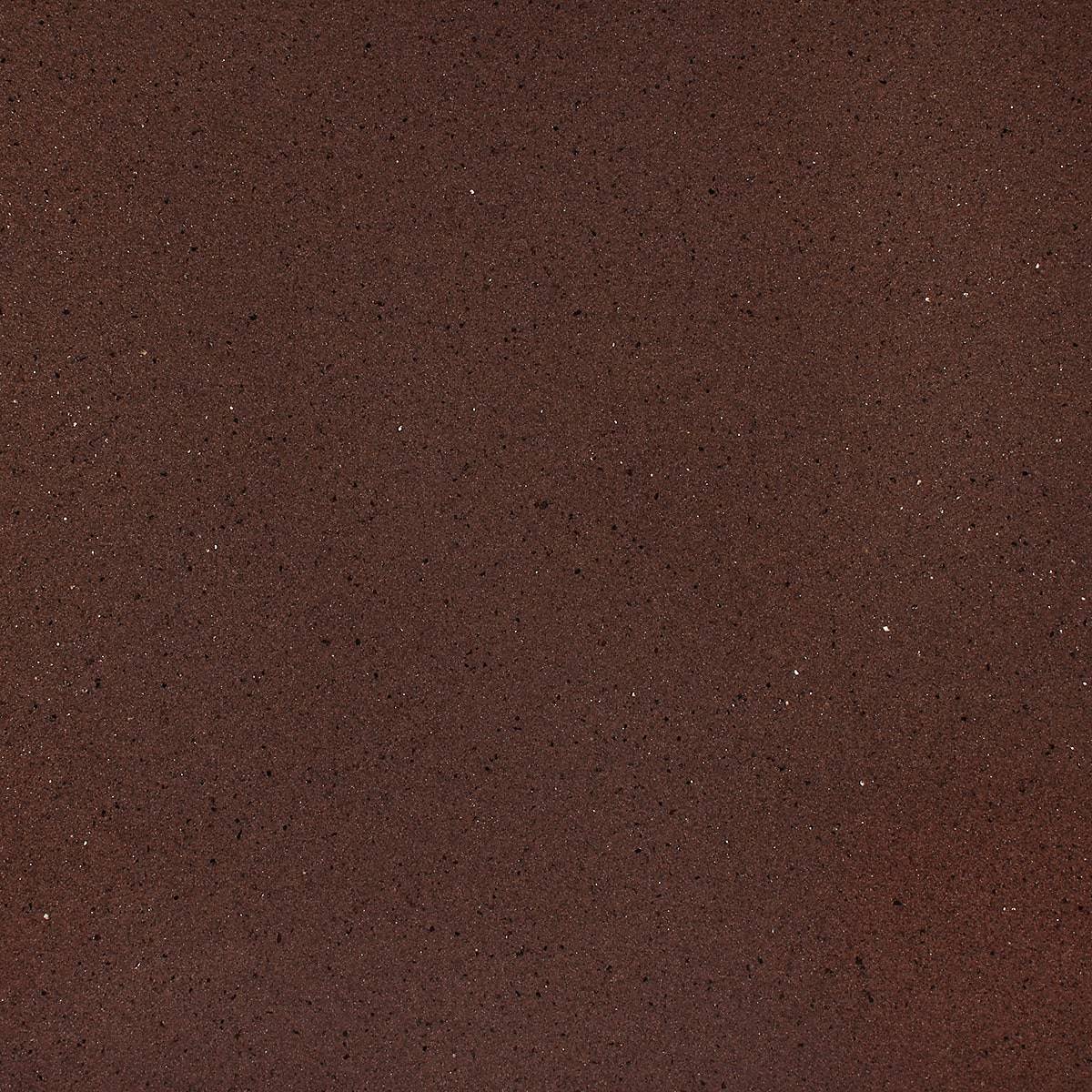

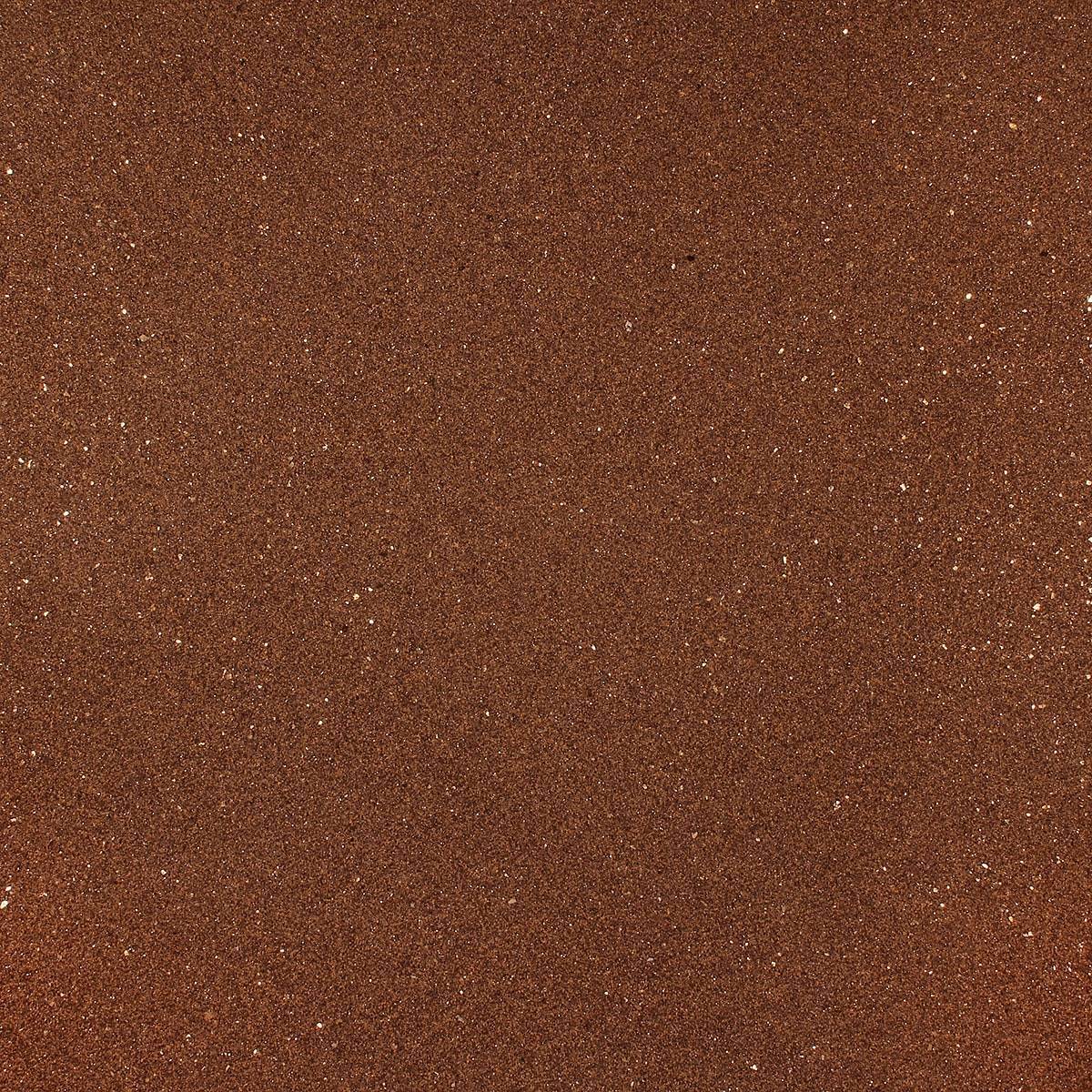

Colors

KAM/001

KAM/002

KAM/003

KAM/004

KAM/005

KAM/006

KAM/007

KAM/008

KAM/009

KAM/010

KAM/011

KAM/012

KAM/013

KAM/014

KAM/015

KAM/016

KAM/017

KAM/018

KAM/019

KAM/020

KAM/021

KAM/022

KAM/023

KAM/024

KAM/025

KAM/026

KAM/027

KAM/028

KAM/030

KAM/031

KAM/032

KAM/033

KAM/035

KAM/037

KAM/038

KAM/039

KAM/040

KAM/041

KAM/042

KAM/044

KAM/045

KAM/046

KAM/047

KAM/048

KAM/049

KAM/050

KAM/051

KAM/052

KAM/0503

KAM/054

KAM/055

KAM/061

KAM/67

KAM/056 + transparent mica

KAM/057 + transparent and brown mica

KAM/058 + transparent mica

KAM/059 + transparent and brown mica

KAM/060 + transparent mica

KAM/063 + transparent mica

KAM/064 + brown mica

KAM/065 + brown mica

KAM/066

KAM/068 + transparent mica

KAM/069 + gold and brow mica

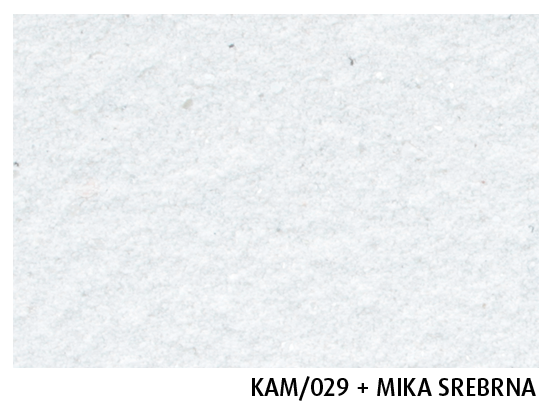

KAM/029 + silver mica

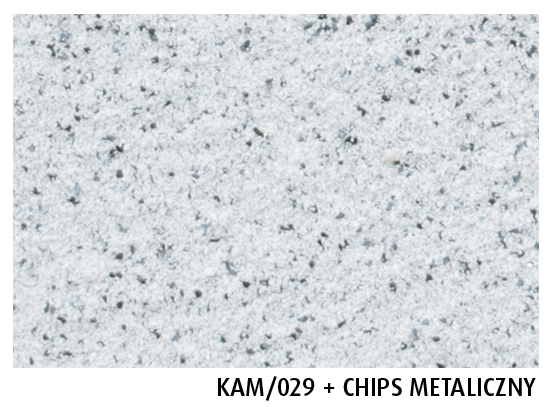

KAM/029 + metalic chips

KAM/034

Downloads

- Katalog Francesco GUARDI Collezione.pdf

- Karta charakterystyki 'TYNK KWARCOWY Francesco Guardi Collezione'wer 7 2023.pdf 0.39 Mb

- Protokół Oceny i Weryfikacji Stałści Właściwości Użytkowych Wyrobu LAKMA... (1).pdf

- AH TYNK KWARCOWY FGC do 12.08.2027.pdf 0.52 Mb

- KDWU LAKMA TERM ST REPAIR.PDF

- KOT LAKMA TERM ST REPAIR 4.pdf 2.00 Mb

- ETA LAKMA TERM ST-.PDF 1.33 Mb

- LAKMA TERM ST- EN.PDF

- DWU LAKMA TERM ST LAK.001.2017 wydanie 2024.pdf 0.26 Mb

- LAKMA TERM WM- EN.PDF

- ETA LAKMA TERM ST.PDF 1.33 Mb

- NRO LAKMA TERM ST.pdf 0.51 Mb

- Protokół Oceny i Weryfikacji Stałści Właściwości Użytkowych Wyrobu LAKMA....pdf

- Certyfikat Stałości Właściwości Użytkowych LAKMA TERM ST.PDF

- Certyfikat Stałości Właściwości Użytkowych LAKMA TERM WM.PDF

- DWU LAKMA TERM WM.PDF

- TDS QUARTZ RENDER ENG.pdf 0.19 Mb

With this product you’ll need

QUARTZ RENDER

Where to buy

Where to buy Centrum dekoracji

Centrum dekoracji Contact a Sales

Contact a Sales