Quartz wall cladding panels

Description

Francesco GUARDI Collezione quartz panels are an innovative form of wall cladding, constituting the perfect alternative for natural stone or ceramic panels. The panels are highly resistant to weather conditions, mechanical damage, thermal stresses, contamination and biological corrosion. Wall cladding is easy to assemble, does not cause excessive load on the façade and does not require special fixing systems.

- it is the perfect alternative for natural stone or ceramic panels

- for use indoors and outdoors

- easy and simple assembly and machining

- high resistance to weather conditions and mechanical damage

- exceptional decorative effect

- does not cause excessive load on the façade

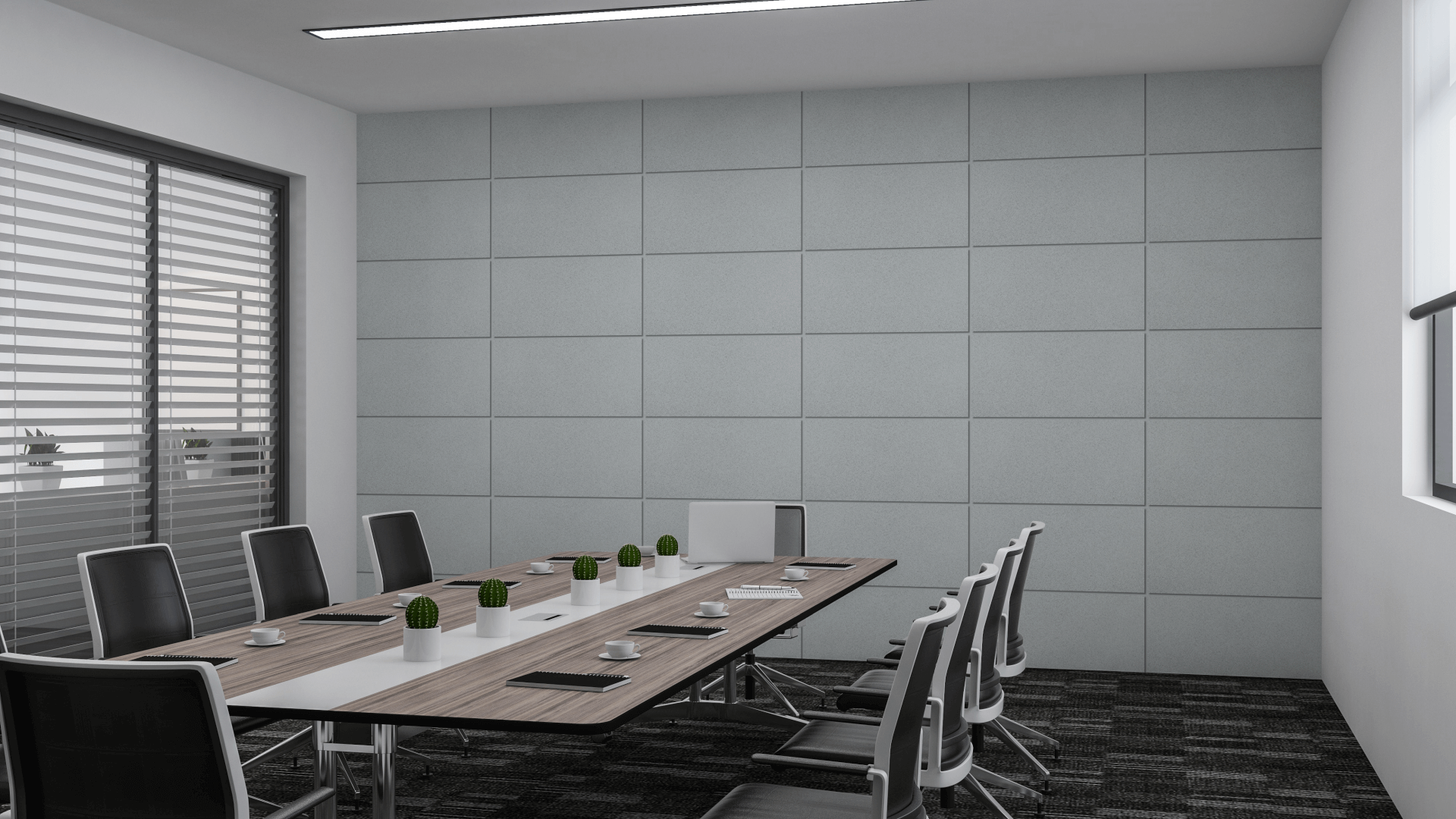

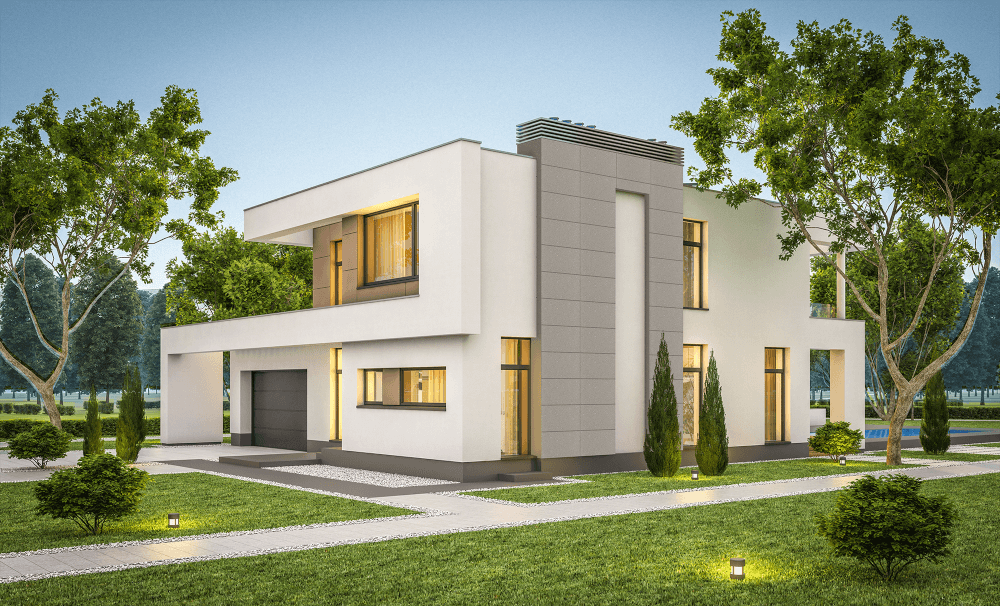

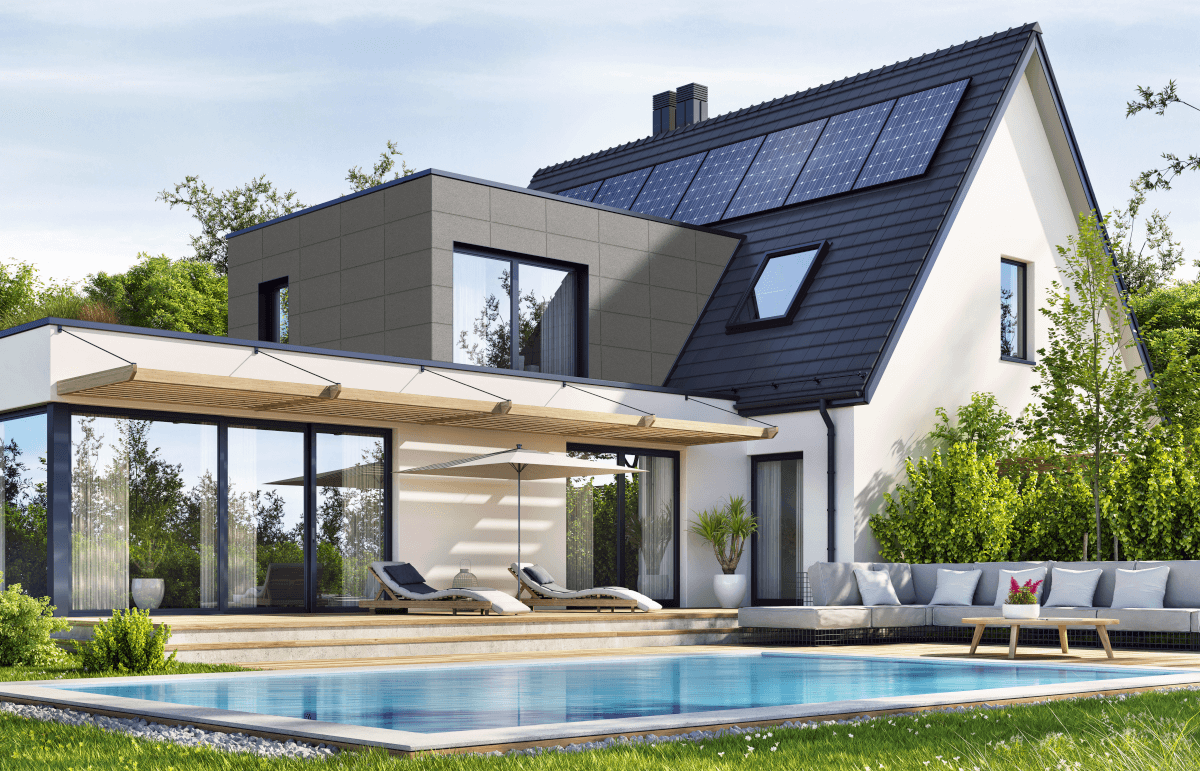

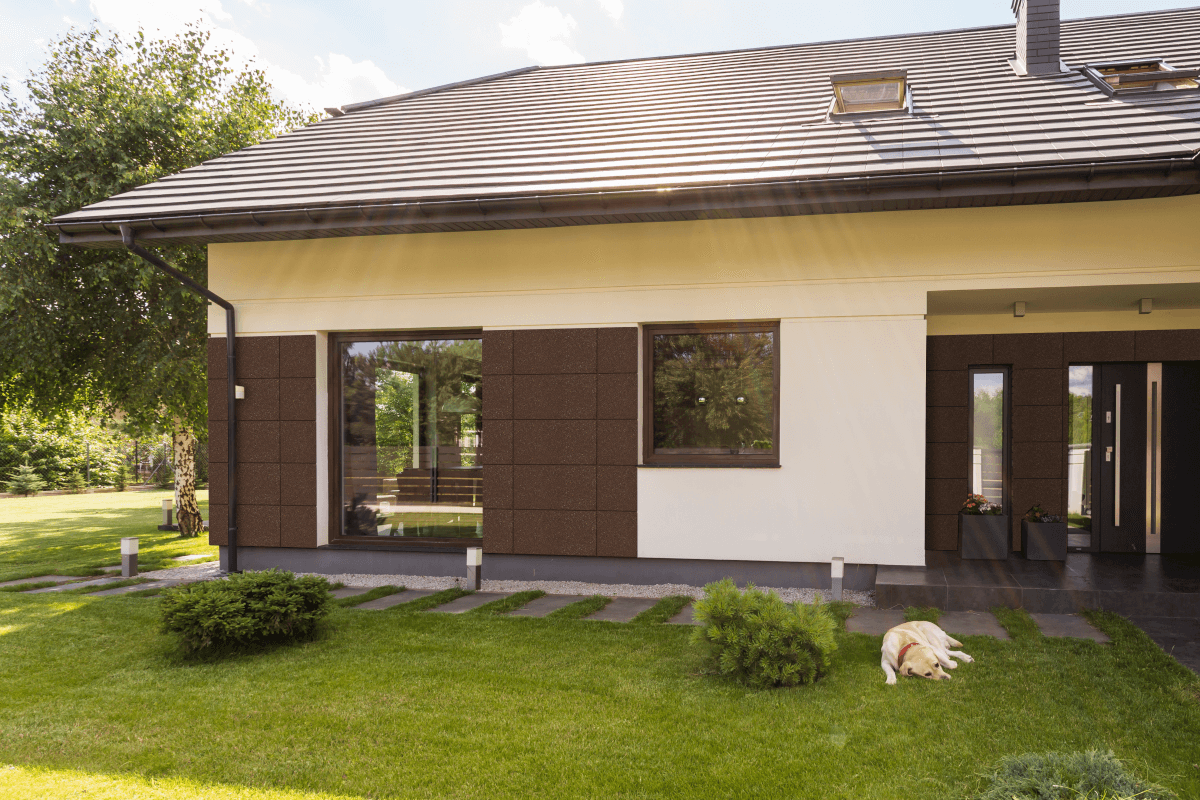

Francesco GUARDI quartz panels are designed for decorating internal and external building walls - including entire façades in single and multi-family development. They are perfect for covering fragments exposed to operational loads e.g. plinths, corridors, staircases and as ornamental decoration of selected fragments of internal walls and ceilings.

Additionally, panels can create a protective and decorative façade finish when insulating walls with LAKMA® TERM ST DEKOR thermal insulation systems.

Application

hallway/staircase

Garage

living room

exterior walls

How to use

- Surface preparation:

Quartz panels should be applied on solid, durable and perfectly even surfaces. The surface should be clean, dry, free of greasy stains, dust, mechanical contamination, chippings disconnected from the surface, as well as biological and chemical aggression. New cement plasters should be covered after 3–4 weeks of air drying. Any defects or unevenness should be filled. Before gluing the panels, a thoroughly dried surface should be coated with the GUARDI primer in a color similar to the color of the board – primer color will determine the final color of the joint. Before applying the GUARDI primer, absorbent and dusty surfaces should be primed with the Fixgrunt U agent. Remove any signs of biological invasion on the surfaces using Biotox Total. A substrate consisting of the SYNTEKOL PSW adhesive mortar, constituting the reinforcement layer, should be coated with the primer once binding is finished, i.e. after at least 3 days from when it was made, if drying under optimal conditions (temp. +20°C, humidity 60%). You may begin gluing the panels after the GUARDI primer has dried, i.e. at least 24 hours after finishing primer application, if drying under optimal conditions. Panels should only be used on vertical surfaces without capillary rise.

If used on partitions in the ETICS system, insulated with EPS or XPS styrofoam boards, reinforcement layer thickness should be at least 4–5 mm.

Application:

In order to minimize waste, panel layout on the surface should be appropriately planned before application. Panels may be installed with an appropriate gap (joint) or neatly fitted together. Surfaces should be evenly covered with adhesive, using a 2–3 mm notched trowel. Apply the adhesive in stages to glue the panels to the undried layer – before the so-called skin effect occurs. If the adhesive dries, remove it and replace with a new layer. Press the panel firmly to the surface so that the previously applied adhesive covers its entire bottom surface, carefully squeezing any excess beyond the panel board. You can use a pressure roller or a float for this. Collect excess adhesive immediately and wash the entire surface with a damp sponge. Panels cannot be installed with an uneven adhesive cover.

Painting:

Mix the varnish thoroughly before use (avoid foaming) and, depending on the painting technique, dilute with water (max. 3%). Apply the varnish twice with a roller with a fleece thickness of approx. 9 mm, avoiding thicker areas or foaming. Cover the joints thoroughly with the varnish using a paintbrush. During painting works, pay attention to avoid any thicker varnish areas. Apply the second layer once the first layer is dry, i.e. after at least 4 hours. Weather conditions during works and within 24 hours after applying the last layer: temp. between +10°C and +25°C, air humidity approx. 55 ±5%, without direct sunlight, wind and precipitation. Brief contact with water of the coated surface is admissible 24 hours after the second layer application. Full performance is achieved after 28 days from applying the last finish layer. Lower air temperatures and higher humidity increase drying time.

Further information:

Due to the presence of natural raw materials, in order to achieve the best aesthetic values, we recommend completing surfaces that constitute a separate whole in one performance stage, using material from a single order from the same manufacturing batch. Perform works with surface and ambient temperatures between +5°C and +25°C, avoiding direct sunlight, both during works and air drying. Do not apply at air humidity above 80%. Data included in this sheet is provided for a temperature of +20°C and a relative humidity of 60%.

Technical specification

Primer

Preparat Gruntujący Guardi w kolorze Panela

Adhesive

Klej Polimerowy do Paneli Kwarcowych

Finishing coat

Lakier zabezpieczający elewacyjny

Dilution/Cleaning of the tools

water

Panel dimension

450 mm x 900 mm x 3 mm

Colours

10 Francesco Guardi colours

Downloads

- AH PANEL KWARCOWY FGC do 14.02.2027.pdf 0.55 Mb

- ATEST RADIACYJNY PANEL KWARCOWY.PDF 0.27 Mb

- TDS QUARTZ WALL CLADDING PANELS ENG.pdf 0.08 Mb

- DWU LAKMA ST DECOR.pdf 1.41 Mb

- KOT OKŁADZINY DEKORACYJNE.pdf 0.69 Mb

- Krajowa Deklaracja Właściwości Użytkowych LAK_008_2023.pdf 0.87 Mb

- KT Okładziny ścienne_Panele kwarcowe.pdf 0.49 Mb

Quartz wall cladding panels

Where to buy

Where to buy Centrum dekoracji

Centrum dekoracji Contact a Sales

Contact a Sales